Choosing the correct specific type of welded wire mesh for the given undertaking is crucial about the sturdiness, security, and look. As indicated earlier, several factors have to be considered when one is deciding on which welded wire mesh to use.

Factors to Consider When Selecting Welded Wire Mesh

The primary physical characteristics you need to consider when choosing welded wire mesh are the wire size and the wire gauge, the sizes of the mesh holes, and the type of coating. When you vet these specifications, you will be in a position to search and determine the product that meets your specific needs.

Different Wire Diameter Options, Wire Gauge

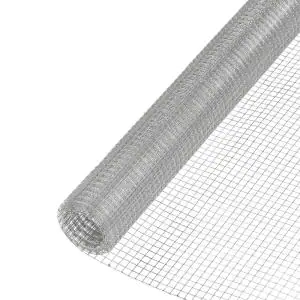

The sizes of the wires in the mesh can be inches or millimeters, and they refer to the diameter of the cables used, both the horizontal and the vertical wires. Wires are available in sizes of 0. 135”, 0. 148”, 0. 192” and 0. 225”. The wire gauge is another specification whereby the welded wire mesh duty rating is featured with the prospect of an increased gauge number.

Thicker wires or wire cross-sections and lower cross-sectional dimensions have higher resistance to impact, pressure, and weight load. Meshes of higher tensile, like 0. 148” diameter, having a six gauge rating, are used for security barriers or parking garage spaces. Fine wires used in minor obstacles such as tree guards or partitions are of 0. 135” diameter and 14 gauge rating.

Understanding Mesh Sizes

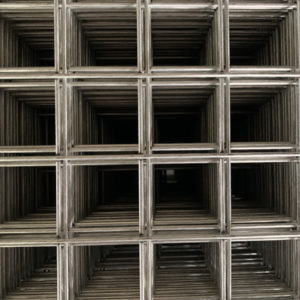

The mesh size, in this case, means the measurement of the apertures that are formed between the crossing wires. Standard mesh sizes are from 1 inch by 1 inch to the coarser 6 inch by 6 inch mesh sizes. The measurements refer to the vertical and horizontal distances between the center of one unit and the center of its neighboring unit.

Barrier or cage type curtains with small mesh opening of 1in x 1in or 2 in x 2 in offer better protection. These are larger meshes, enable excellent breathability and visibility, and are commonly used for fencing and building screens. Choose the mesh sizes that suit the security and visibility requirements of the place.

Coating Options: Comparing Galvanized Steel to PVC Coated

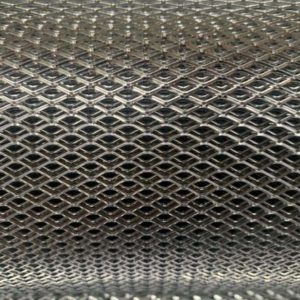

Welded wire mesh is available galvanized and with PVC-coating. Galvanized mesh, the zinc coating, protects the product against rusting and corrosion. The material of PVC-coated mesh is galvanized for anti-corrosive properties. It has an extra plastic layer for enhanced climatic resilience.

The galvanized welded wire mesh is ideal for most applications, including the general purposes of the applications where the wire mesh is used. Of course, the longevity of the product is high when placed in an outdoor environment. The PVC-coated mesh has a better ability to withstand any adverse conditions that contain water, salt, chemicals, or moisture. It must be noted that though PVC-coated mesh is more costly initially, it indeed has a life of more than double the life of the galvanized mesh.

How to Choose the Right Welded Wire Mesh: A Step-by-Step Approach

Follow these steps when selecting an appropriate welded wire mesh:

- Finding its use – This will involve weighing on factors such as security requirement, visibility, weight bearing, and exposure to weather or chemical agents. This will determine the strength and protective coating needed.

- Assess the surroundings – If the environment is outdoors, then the object or structure should be sturdy and long-lasting. Moving to the indoor application, the possibilities are more diverse, yet the effects should be considered.

- Evaluate mesh details – By looking at the mesh’s wire gauge, diameter, and sizes of meshes, you will identify a type that can adequately handle expected stress levels. The measurements must be tailored to match the intended structure.

- Coating materials – Choose between galvanized or PVC-coated materials depending on the available budget, longevity, and geographical location. Galvanized is suitable for elementary weathproofing while PVC-coated is suitable for extreme climate conditions.

- Read certifications – Ensure that the welded wire mesh is produced to conform to ASTM international standards to guarantee the best quality of the product. Reliable manufacturers will always be able to avail some sort of document.

- Seek advice from specialists – If there is an essential need for a specific type of welded wire mesh, consult with the welded wire mesh professionals regarding customization of the product by specialized requirements.

Adhering to the guidelines outlined above will get you to the perfect welded wire mesh product that will provide superior security, as well as clarity and great endurance for your next project.

Conclusion

Basically, the welded wire that you choose should be able to meet the specific demand and the conditions of the given project. While using the wire gauge, the size of the mesh opening, the type of finishing, strength, and certification, one can be able to choose the proper mesh that will suit a given application based on the amount of strength, visibility, and security desired alongside the expected life span. For more involved projects, it is appropriate to seek consultation from specialists to get the welded wire mesh products that will meet the required needs. Recall the main decision parameters, and you will be on track to achieve the optimal mesh for your next project.